Governance

Sustainability Development Committee

To address evolving sustainability trends and seize accompanying opportunities and challenges, the ASUS Sustainability Development Committee was established in 2025. Comprised of five independent directors and the two Co-Chief Executive Officers, it serves as ASUS’s highestlevel sustainability governance body. The Committee reviews the Group’s sustainability management operations and execution progress and reports annually to the Board of Directors. Under its oversight, the Sustainability Center convenes quarterly meetings with Sustainability Management Representatives from each subsidiary to jointly formulate and implement action plans addressing Group-wide sustainability issues. Supply chain management is one of the key focus areas, and subsidiaries will be required to adopt the Responsible Business Alliance (RBA) Code of Conduct and conduct audits of their supply chains.

ESG Committee

To strengthen horizontal cross-unit communication within the company, ESG Committee was established in 2022. Committee members were from each business unit as well as the design center, certification,marketing, sales and other support units. We consolidate the sustainability progress and requirements of each unit, facilitating the centralized integration of resources. This ensures the efficient allocation of resources, enabling all departments to progress in a unified sustainability direction.With respect to procurement and the supply chain, we place particular emphasis on implementing sustainable sourcing strategies to ensure that every link in the supply chain complies with current international regulations and emerging trends. Through ESG Committee meetings, we not only strengthen the internal team’s understanding of and commitment to the core values of sustainable development, but also encourage active participation in sustainability practices across the entire supply chain.

Sustainability and Green Quality Management Center

ASUS established a unit dedicated to sustainable development in 2009 to monitor global sustainable development trends, analyze sustainability issues in governance, environment, and society. It integrated the core of operation with our innovation in product and service to form strategic sustainable direction to execute relevant programs. The Sustainability and Green Quality Management Center is established with the CEO serving as the highest-level manager, as mandated by the Chairman. The CEO is responsible for overseeing the sustainability projects and ensuring the achievement of goals related to material issues. The unit is led by the Chief Sustainability Officer (CSO) who is responsible for analyzing the trend of global sustainability, managing sustainability policy, objectives, and actions. The CSO regularly reports to the Board of Directors each year and submits the policies and targets, key sustainability projects and the performances for review.For sustainable supply chain management, the Sustainability & Green Quality Management Center has established a Supplier Code of Conduct to promote the protection of labor rights, responsible mineral sourcing, and the management of initiatives to reduce the environmental footprint of manufacturing.

GreenASUS and SERASUS Committee

To facilitate cross-departmental coordination on highly impactful issues such as products, supply chains, and organizational operations, ASUS established the GreenASUS Management Committee and the SERASUS Management Committee. Senior management appoints representatives to oversee the Company’s ISO 9000 Quality Management System, QC 080000 Hazardous Substance Process Management System, ISO 14001 Environmental Management System, and others. These committees regularly communicate information related to environmental safety, health, and management systems to all employees. Members are drawn from business units, procurement, customer service, administration, and legal departments, enabling horizontal communication and coordination across departments. This ensures the effective allocation of resources and aligns all ASUS employees toward a unified sustainability direction, truly integrating sustainability into core operations as a component of the Company’s competitive advantage.

Strategy

According to estimates by the Intergovernmental Panel on Climate Change (IPCC), the value of global ecosystem services amounts to USD 150 trillion, with approximately 47% of national GDP generated from services provided by biodiversity. However, the Intergovernmental Science- Policy Platform on Biodiversity and Ecosystem Services (IPBES) has identified economic and social activities as major sources of pressure leading to environmental degradation. The key drivers include changes in land and sea use, climate change, direct exploitation of natural resources, pollution, and invasive species. Incorporating these five primary drivers of natural environmental loss into value chain risk assessment and management reviews can help mitigate the environmental impact of a company’s value chain.

Statistics show that over 80% of Fortune 500 companies have set carbon reduction or netzero targets, yet only 6% have established goals to reduce impacts on and restore biodiversity. Furthermore, BlackRock, in its article “Our Approach to Engaging on Natural Capital,” noted that more than half of global GDP (approximately USD 58 trillion) is moderately or highly dependent on the natural environment, yet only a small portion of natural capital’s value is adequately reflected in market pricing. As pressures on natural capital intensify and related policies and regulations become increasingly stringent, asset prices will progressively adjust to account for nature-related risks and opportunities. For companies whose strategies or supply chains are heavily dependent on natural capital, effectively managing nature-related risks and opportunities has become a critical factor in generating long-term financial returns.

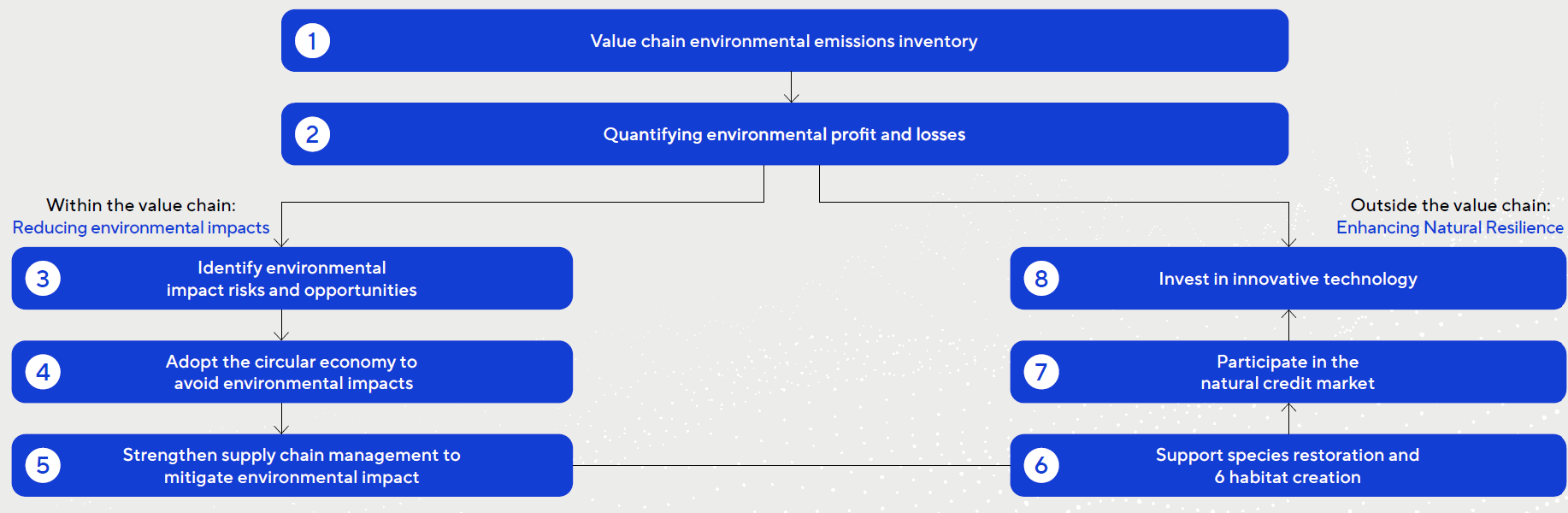

In response to the growing attention from external capital markets on nature-related issues, as well as the requirements of the United Nations Sustainable Development Goals (SDGs) and the Kunming- Montreal Global Biodiversity Framework (GBF), ASUS has launched biodiversity monitoring initiatives, established a Biodiversity Policy, and developed a Natural Capital and Biodiversity Strategy Map. This dual-track approach—comprising “value chain management” and “beyond value chain actions”—aims to reduce environmental impacts and enhance ecological restoration.

Within value chain management, ASUS identifies and assesses the dependence and impact of its operation centers and supply chain on nature, aligning with the Science Based Targets Network (SBTN) AR3T (Avoid, Reduce, Restore, and Regenerate) action framework. Through the implementation of climate action, circular economy practices, and strengthened supply chain environmental management, ASUS seeks to minimize the negative impacts of its operations on the environment.

Beyond the value chain, ASUS will engage in initiatives such as the restoration of endangered local species and the exploration of nature-related innovative technologies to enhance ecosystem resilience, striving to realize the vision of harmonious coexistence with nature.

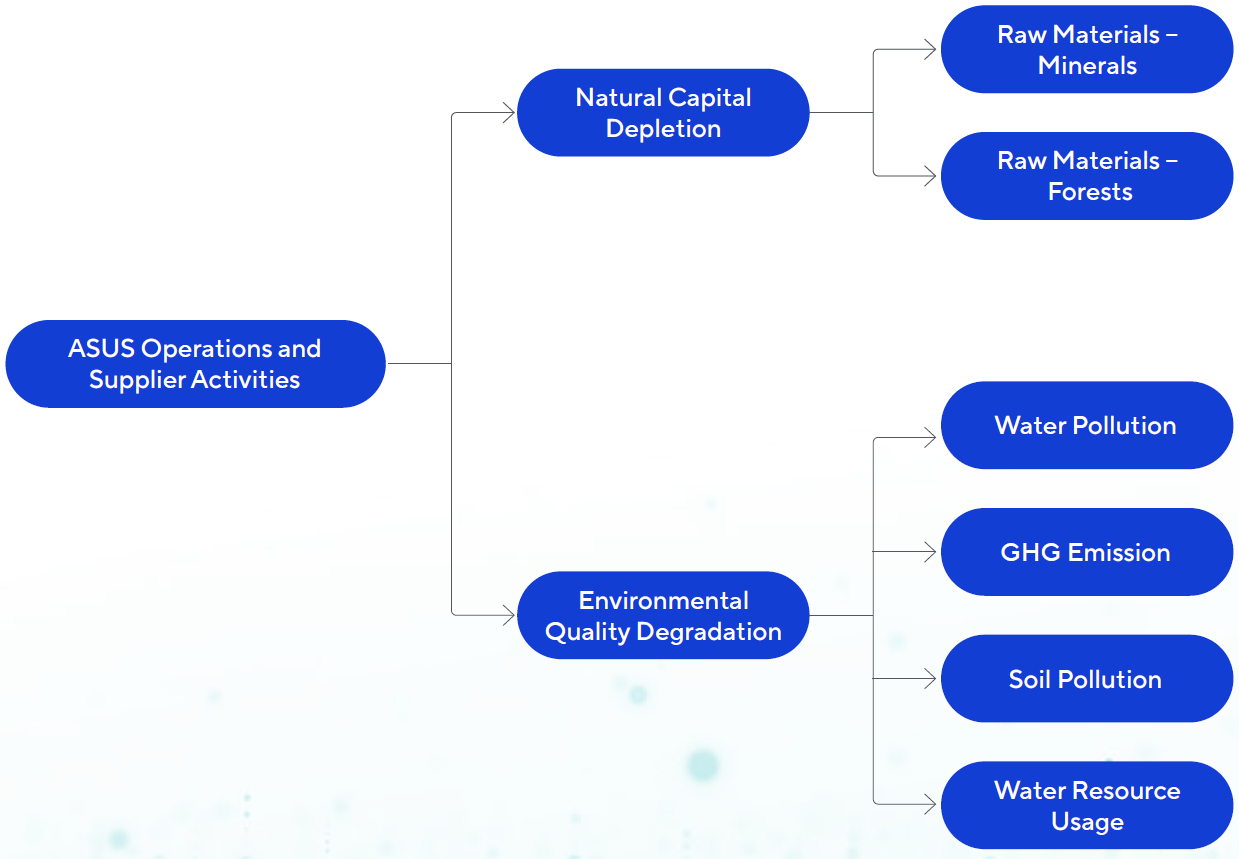

Defining the Dimensions and Scope of Natural Capital Impacts

ASUS identifies the impacts of value chain activities on natural capital, which can be categorized into two main types based on their sources: natural resource depletion and environmental quality degradation. Natural resource depletion primarily arises from raw material extraction activities, including the mining of mineral resources and the utilization of forest resources, which directly consume the stock of natural capital. Environmental quality degradation encompasses the negative impacts caused during operations, including water pollution, GHG Emission, soil contamination, and water consumption, all of which affect environmental quality.

(1) Natural Capital Depletion: Raw Material Extraction and Use

The greatest impact of ASUS products on natural capital comes from the extraction of raw materials within the supply chain, such as minerals and forest resources. According to the 2021 report by the Electronic Product Environmental Assessment Tool (EPEAT), a voluntary environmental labeling program, electronic products contain 40 types of critical metals. For example, metals account for approximately 70% of the raw materials in laptops and as much as 79% in desktops. The mining of these metals causes large-scale environmental destruction, alters landscapes and terrain, affects natural scenery, and severely disrupts local biodiversity balance. Research indicates that upstream mining industries have a biodiversity pressure index of 6%, while logging industries score as high as 11%, with the main sources of impact being the overexploitation of natural resources and changes in land use.

2) Environmental Quality Degradation: Environmental Impacts of Value Chain Activities

ASUS’ operational activities have direct negative impacts on the environment, primarily including greenhouse gas emissions, water pollution, and solid waste generation. These forms of pollution directly affect the quality of natural habitats and worsen living conditions for species. According to research by the German League for the Environment and BCG in The Biodiversity Imperative for Business, the manufacturing sector has a biodiversity pressure index of 7%, with sources of impact including land-use change, climate change, and environmental pollution. In addition, water resource availability poses an increasing risk to the electronics manufacturing industry. The United Nations World Water Development Report 2023 estimates that by 2030, nearly half of the global population will face severe water stress, and by 2050, the urban population experiencing water shortages will be twice that of 2016. Extreme climate events exacerbate water resource fluctuations, with every 1°C increase in global average temperature reducing water availability by 20%. Furthermore, between 2001 and 2018, nearly three-quarters of natural disasters were waterrelated. International voluntary environmental labeling programs such as EPEAT and TCO have begun strengthening water resource management requirements, encouraging the electronics industry supply chain to adopt more proactive water management measures.