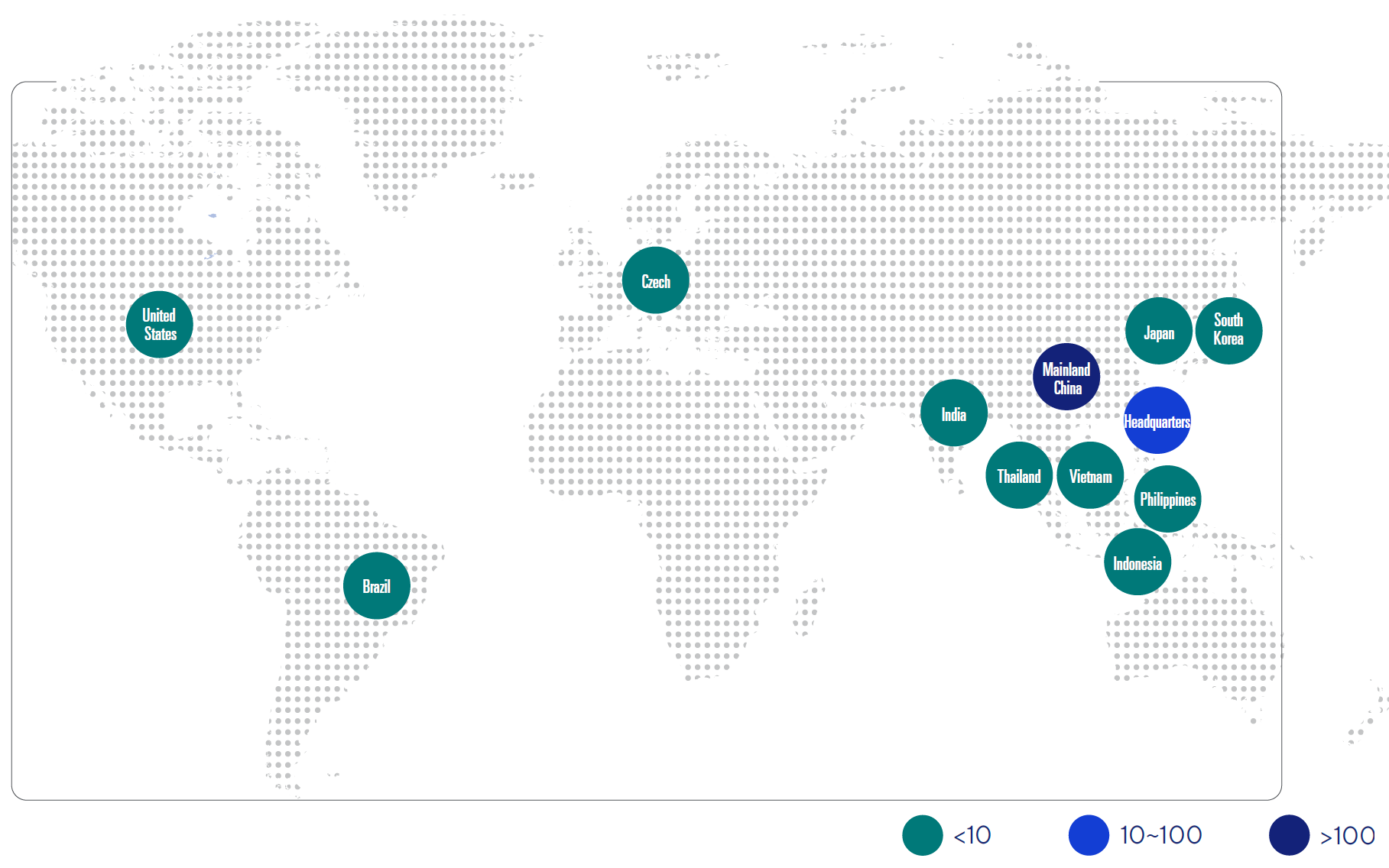

ASUS is committed to driving sustainable procurement and collaborates with 693 suppliers worldwide to build a resilient and sustainable supply chain. We embed sustainability principles into our procurement decisions, implementing them at every stage—from design and raw materials to manufacturing, use, and end-of-life recycling.

Beginning in 2024, ASUS will bring its key production affiliated subsidiaries—where we hold more than 50% equity and operational control—under this management scope, ensuring that the entire Group’s operations and supply chain uphold the highest standards of responsible manufacturing and fulfill our corporate social responsibility and sustainability commitments.

We categorize suppliers according to our procurement model into three types: raw material manufacturers, component manufacturers (including panel suppliers, motherboard producers, IC component suppliers—such as CPU, SSD, HDD, RAM, and GPU manufacturers—and power supply providers), and product assembly facilities . We identify key suppliers based on procurement amount and key technical indicators.

Procurement Amount Ratio of Tier 1 Key Suppliers

| Supplier Categories | Description | The Number of Suppliers / Procurement Ratio |

|---|---|---|

| Tier 1 Suppliers and Product Assembly Facilities | All continuously trading suppliers | 693 |

| Tier 1 Key Suppliers | Quarterly procurement amount reaching NT$2.5 million, key technical indicators | 110 |

| Procurement Amount Ratio of Tier 1 Key Suppliers | - | 82.6% |

| Non–Tier 1 Key Suppliers | Key Plastic Manufacturers | 3 |

ASUS considers sustainable procurement a critical factor, integrating environmental, social, and economic indicators into supplier evaluations, and requiring suppliers to comply with relevant laws and regulations to ensure the sustainability of the supply chain. Our measures for promoting sustainable procurement include:

- Formulating a Sustainable Procurement Policy that clearly defines our goals and principles as guidelines for supply chain sustainability.

- Incorporating sustainable procurement requirements into the Supplier Code of Conduct to communicate ASUS’ expectations to suppliers.

- Establishing a supplier sustainability assessment mechanism that integrates sustainability criteria into supplier selection and risk management indicators, and promotes continuous improvement through regular audits.

- Enhancing suppliers’ sustainability management capabilities to reduce environmental impact, improve labor rights, and strengthen supply chain resilience and accountability.

- Raising procurement personnel’s sustainability awareness by making sustainability trends and management practices mandatory training for procurement and outsourcing management teams.

Risk Evaluation and Classification Management

The management consists of three phases-new supplier approval, continuous risk management, and performance evaluation. These phases apply to product assembly facilities, component manufacturers, and raw material manufacturers. This approach ensures that all supplier categories are incorporated into the sustainability management framework.

Phase 1

New Supplier Approval

The entrance barrier for becoming ASUS’ qualified suppliers requires possessing ISO 9001 and ISO 14001 certifications, signing the Declaration of Supplier Code of Conduct, and passing the audits on Quality, Hazardous Substance Free, and Corporate Social Responsibility.

Phase 2

Continuous Risk Management

ASUS integrates four dimensions—national geopolitics, industry and product characteristics, controversy events, and supplier criticality—to develop risk indicators covering the RBA Code of Conduct, hazardous material and process management, brand reputation, labor protection, continuous improvement, management systems, and labor intensity. Each year, we target all continuing suppliers, as well as those suppliers and product assembly facilities with quarterly procurement amounts reaching NT$2.5 million, to conduct supplier risk self-assessments.

Suppliers that self-assess as high risk, or those with prior environmental or social adverse events, undergo second-party or third-party onsite audits per the ASUS Supplier Code of Conduct; medium- and low-risk suppliers are subject to thematic or document audits. The annual audit scope covers product assembly facilities and component manufacturers.

Furthermore, all suppliers must participate in annual surveys covering Responsible Minerals, Greenhouse Gases, Water Footprint, and Waste. Through audits and capacity-building support, ASUS manages potential risks related to labor, health and safety, environment, and business ethics, preventing adverse impacts on governance, environment, and society, thereby ensuring a stable and sustainable supply chain.

Phase 3

Performance Evaluation

In our Quarterly Business Review (QBR), ASUS evaluates traditional metrics—quality, cost, technology, delivery, and service—alongside sustainability performance indicators such as ethical business conduct, environmental protection, labor rights, and occupational health and safety. The outcomes of these evaluations inform order allocation and decisions on ongoing partnerships: top-performing suppliers are awarded additional resources, and we leverage our brand influence to drive continuous improvement across the supply chain.

If a supplier violates any corporate social responsibility requirements and significantly impacts the environment or society in the country of operation, or fails to pass audits for two consecutive years, ASUS reserves the right to terminate or dissolve the contract or collaboration at any time.

Audit and Continuous Improvement

To ensure suppliers comply with ASUS’s management requirements on human rights, occupational health and safety, and environmental protection, in 2024 ASUS identified 100 high risk suppliers based on their self-assessment results and conducted second-party and third party onsite audits in accordance with the ASUS Supplier Code of Conduct, uncovering a total of 1,125 nonconformities, with an overall corrective-action completion rate of 90%. At the same time, all ASUS auditors have completed RBA audit training and obtained certification, continuously strengthening our supply-chain management expertise and execution effectiveness.

Analysis of the 2024 audit results reveals that high-risk nonconformities were concentrated in three areas —labor practices, occupational safety, and environmental management —particularly among high labor-intensity suppliers such as product assembly facilities, mechanical-parts producers, panel suppliers, motherboard manufacturers, power-supply providers, and battery suppliers. ASUS requires suppliers to remediate priority nonconformities within 30 days, major nonconformities within 90 days, and minor nonconformities within 270 days. The failure rates and remediation rates for each category are presented in the report.

For nonconformities related to excessive working hours that remain unresolved, ASUS employs a continuous monitoring and support mechanism, requiring non-compliant suppliers to establish working-hours management and monitoring systems and to report monthly performance for six consecutive months, thereby mitigating overtime risks and ensuring compliance with local regulations and RBA minimum standards.

Improvement Actions

ASUS holds assistance meetings to support suppliers in improving their performance, providing industry best-practice examples to facilitate peer exchange of management experiences. Through sustained coaching, all audit deficiencies have been fully remediated, and the high-risk working-hours issues have been reduced to a low-risk level recognized by the RBA, with ongoing monitoring maintained. Under the established audit and management framework, over 2,500 employee interviews have been conducted over the years, cumulatively safeguarding the fundamental rights of more than 490,000 employees. In 2024, no supplier was disqualified from transactions due to any significant adverse incident.

| Labor Employment | Occupational Safety | Environmental Management |

|---|---|---|

|

|

|

Supplier Grading Management

ASUS adopts the Responsible Business Alliance (RBA) Code of Conduct and applicable regulations as the baseline requirements for supplier management. Leveraging accumulated audit findings, assessment data, and engagement feedback, ASUS has established a supplier management database to serve as the foundation for implementing sustainable grading management. Based on each supplier’s sustainability management maturity and its strategic relevance to ASUS’s business, suppliers are classified into four tiers—Strategic, Potential, Evolving, and Developing—with differentiated management strategies applied accordingly:

- Strategic Suppliers: Suppliers with high sustainability management capability and strong business relevance, prioritized for procurement and engaged as partners in innovation and carbon reduction initiatives.

- Potential Suppliers: Key business partners whose sustainability performance still has room for improvement; through project support, regular audits, and capacity building, their sustainability management maturity is elevated.

- Evolving Suppliers: Suppliers demonstrating solid sustainability performance but with relatively lower business relevance; ASUS encourages their participation in additional sustainability collaborations to gradually deepen the partnership.

- Developing Suppliers: Suppliers with lower procurement volumes and developing sustainability capabilities; ASUS focuses on ensuring compliance with fundamental regulations and the RBA Code of Conduct and periodically reviews their improvement progress.

The grading management mechanism helps ASUS allocate management resources efficiently by tailoring management measures to each supplier category, enhancing communication efficiency and remediation effectiveness, and progressively strengthening the overall supply chain ’s sustainability performance and operational resilience. This mechanism also responds to increasingly stringent international regulations, brand and customer requirements, and investors’ expectations for ESG risk control, demonstrating ASUS’s proactive commitment to a responsible supply chain.

In 2024, ASUS, leveraging supplier industry attributes and global material issues, is focusing its enhanced management actions on the following key areas:

- Human Rights: Centered on “living wage” and “employee organizing rights,” ensuring suppliers comply with international labor standards to safeguard workers’ basic livelihoods and freedom of association.

- Environmental: Concentrating on“biodiversity,” “process chemicals,” and “water resource management,” employing hotspot identification, project-based support, and improvement actions to mitigate the supply chain’s impact on the natural environment and to strengthen preventive management in high-risk regions and processes.

ASUS continuously strengthens its supply chain management through scientific methods and a risk-based approach, investing resources to collaborate with suppliers in upholding human rights and environmental responsibilities, thereby building a resilient and sustainable supply chain.

ASUS has expanded the implementation of the Responsible Business Alliance (RBA) Code of Conduct and framework to encompass ASUS' group. The management methods are detailed in the case study: